There are 2 ways I use to find a sleeve...

One way is using the CR seal pn.

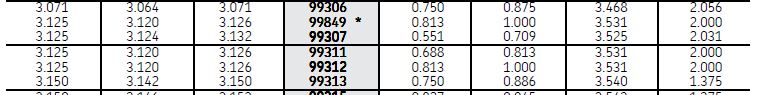

Example; 25082 is the timing cover seal for the SV8's,take the "250" and put "99" in front of that and you have the Speedi-Sleeve pn 99250. This method does not work for all seals/sleeves though.

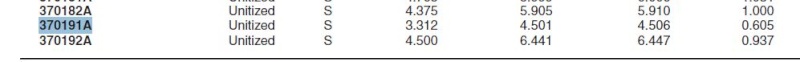

That's when you use the seal ID.

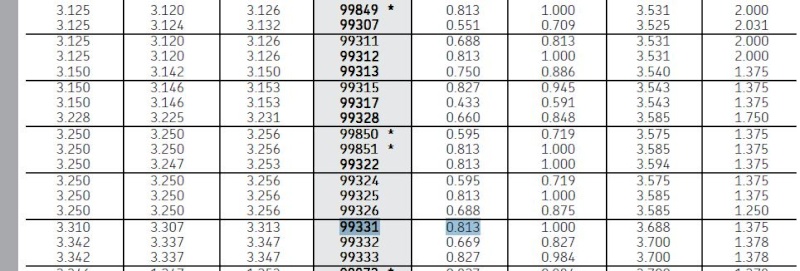

33136 is the CR # for your application,in this case the seal ID 3.3136,just drop the 6. Next go to the Sleeve size chart and find the shaft size (nominal dia.) find the "shaft diameter range" there 2 columns,min. & max.

It looks like I may have goofed here in the initial look up.

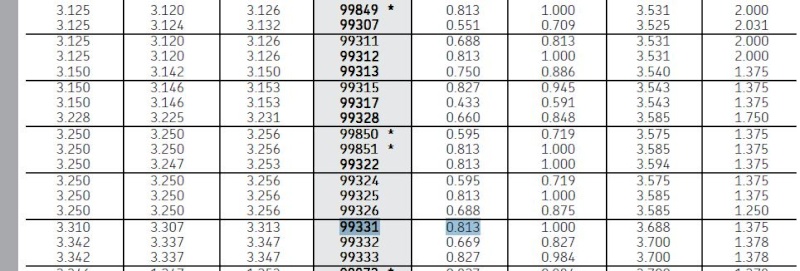

99331 appears to be the right one(?). So it seems I had a brain cramp and dropped the first "3" from the seal # and looked up a SS for a 3.1xx shaft.

Good thing you asked the question!

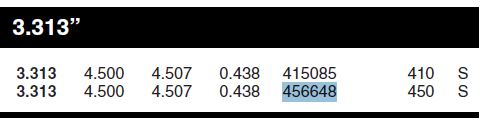

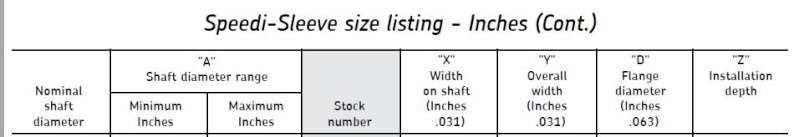

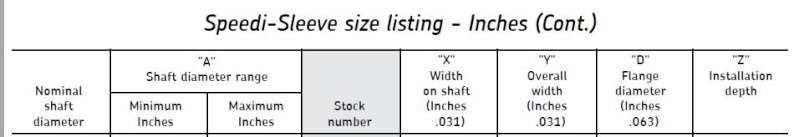

Here's the header for the SS page.

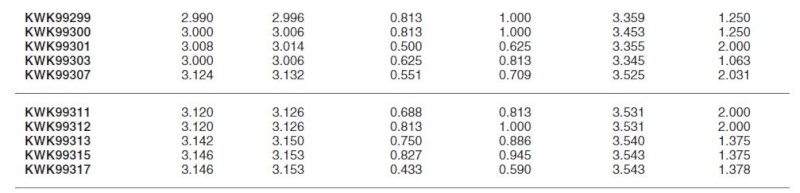

The size range chart.

The installed width of 99331 is highlighted too,not sure why but it's about 13/16".

You did good with the hose etc. pn's. One thing though,22 is a nut and the pn's below it are "Parts not illustrated" which are always marked with an asterisk,see it before the description(?).

Other times you may see $,& or a small "box" after a pn which usually indicates parts included in a kit,which will usually be at the end of the pn's like the PNI #'s. So it's always good to check there. Look up a carb. kit and you'll see what I mean.

Btw,all those "gaskets" listed like #4 and the ones under the front hose are those copper "crush washers" used with banjo fittings,replace any you remove.

I saw the post about that brake shop you found,sounds real old school and my kind of place!

If you want new hoses I think they'd be the best bet,even if you have to match them up and have to go a bit longer as well. I checked all the numbers and only the rear axle # crossed (Dorman). FP Smith shows the front hose but no quantity amt. of how many in stock.

The one with 2 listed,go with the 184143R91,the other seems to be for bulk hose (roll) if what I found is accurate.

I'll bet if you go to that place and tell them what each hose is,they'll have/find or get it. I mean they have the H-vac in stock and had the clutch MC...

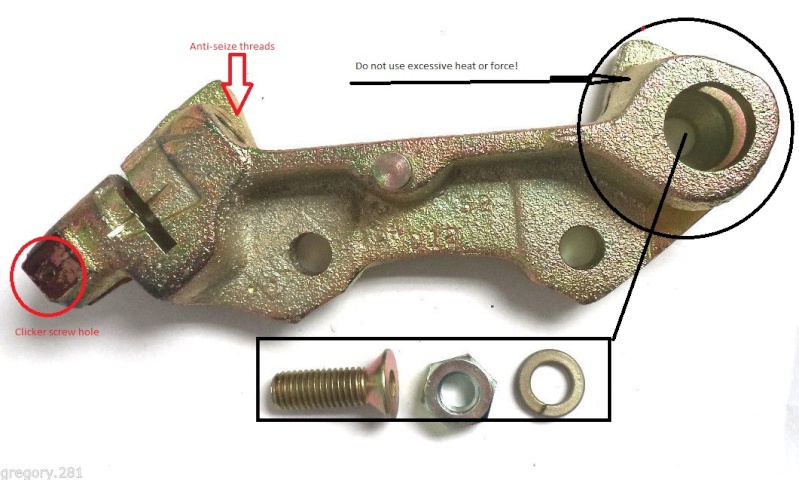

Btw,the HV for your brake code (04011) is 277082C91 (C92 or C93) 2512076 Bendix.

They are probably able to supply everything you need really. Form a good rapport and you might be able to use them even after the move?

12 yrs.exp. in IH dealer parts dept.

Never argue with a fool...

If you don't have anything nice to say...say nothing.

If you don't learn something new everyday...you weren't paying attention.

THINK! Be sure brain is connected before mouth is in gear.

,I even found a 1972 Ford truck service manual and it's not much different than an IH one.

,I even found a 1972 Ford truck service manual and it's not much different than an IH one.