From an IH service manual.

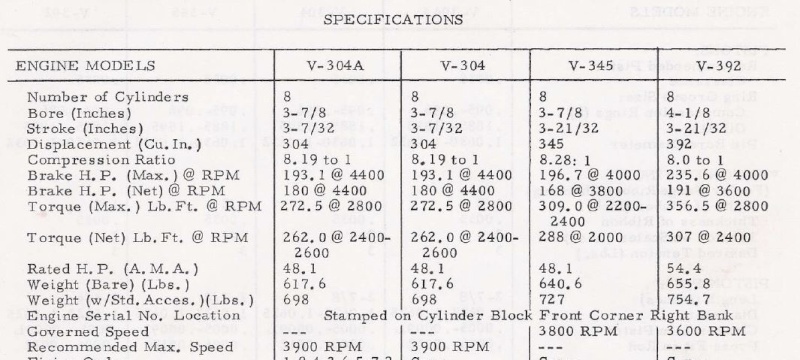

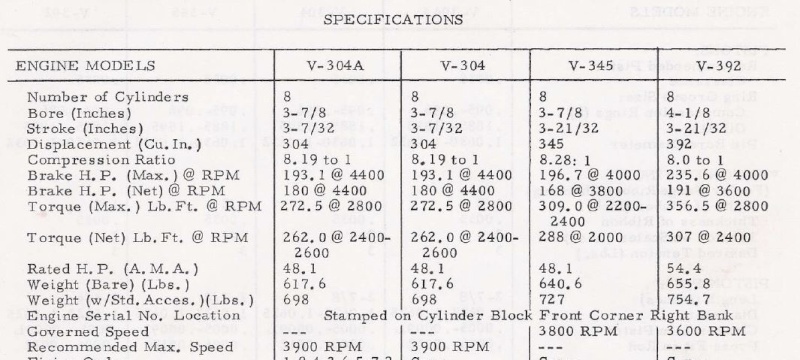

The answer is a 392.

Is the truck you're looking at now a 4dr. cab? If not then WHY are you considering this??? If it's due to the frame issue on the 4x4 there are other way's to remedy such things and the frame can actually be stronger as a result.

I really feel swapping the drive train in a Loadstar is going to open a can of worms.

I really agree with Brian,he has mucho experience with jobs like this albiet with smaller models but with what you propose it's not all that much different. Plus he has the tools to fab what parts which makes a big difference in costs.

If you really want a 4dr. 4x4 though maybe you should be looking for one. The California forest fire service had 100's of them over the years,so did the U.S. forest service. I checked the map and where you are now (the boondocks) I'll bet you can find one.

There is a market for fire pumps and hose,maybe the body. Old hose can be used for things like a restoration or irrigation and if not too old and can pass testing, for fire fighting. There are many rural FD's that can't alway's afford new hose

https://www.google.com/?gws_rd=ssl#q=fire+hose+testing

https://www.google.com/?gws_rd=ssl#q=fire+hose+testingIf the hose is within parameters maybe the local FD would appreciate a "donation"? Put a value on it and you could likely use it as a tax write off as well(?). Plus since firefighters are the most numerous collectors/restorers talking with them could give you leads about the other things.

It's a

real shame the guy with the 4dr. cab has had second thoughts. Putting a

chevy nose on it just ain't right first of all!!! If it's a sheet metal nose they're not really any easier to work under the hood on,sure it's roomier but you still need steps or something to get to anything. Plus where the hood meets the cowl is nowhere near the same shape,maybe with a 50's model it's a little closer but, would look just plain stupid. Same hood to cowl issue with a tilt hood.

Talk about a can of worms!

He'd be

much better off finding a LS tilt hood,as I described elsewhere in this thread it will fit

right as long as you have all the parts to do it.

12 yrs.exp. in IH dealer parts dept.

Never argue with a fool...

If you don't have anything nice to say...say nothing.

If you don't learn something new everyday...you weren't paying attention.

THINK! Be sure brain is connected before mouth is in gear.